| Building A Digital Twin With Predix |

| Written by Kay Ewbank | |||

| Monday, 04 September 2017 | |||

Page 2 of 2

Digital Twins In ActionAn example of the way early warnings can be used is that of an early warning system for bearing failure in an airplane engine.The model of the bearings in the digital twin is being used to continuously monitor the health of the bearings, so allowing customers to predict bearing failures 15-30 days in advance. This means customers can avoid unplanned engine removal, choosing instead to incorporate the engine removals into planned maintenance schedules, and also avoiding the high cost of secondary damage. (click to expand)

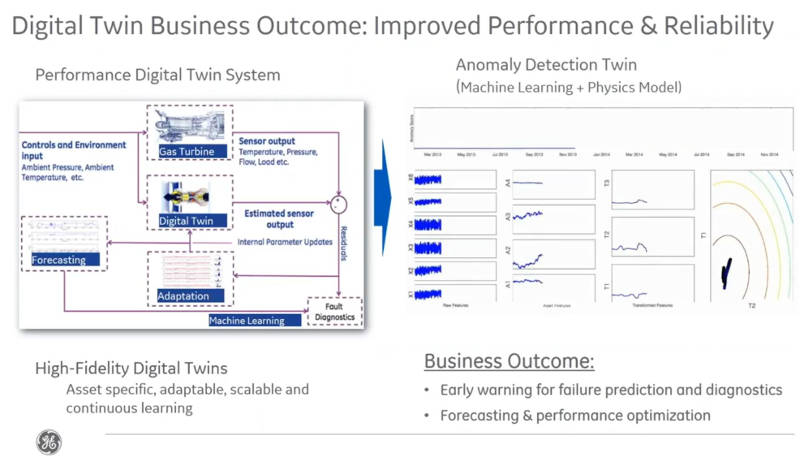

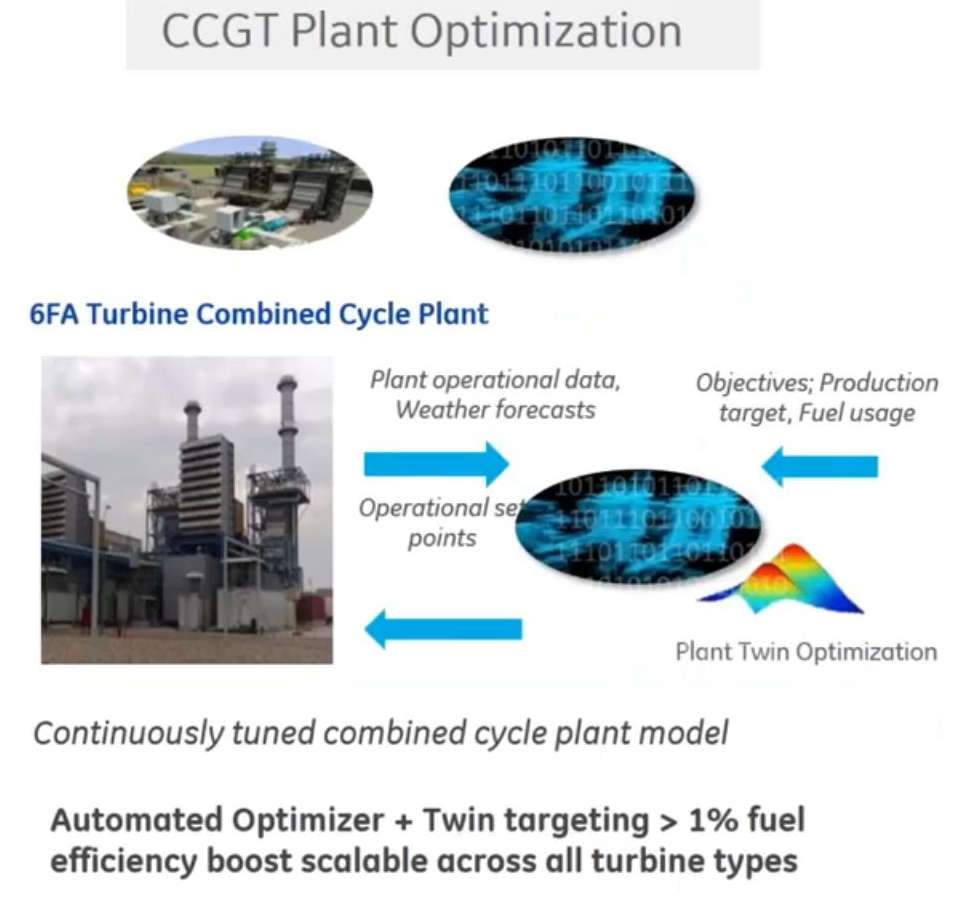

One example of the way Continuous Prediction can be used is that of the monitoring of the Stage-1 Blade of an aircraft engine. By getting insights about potential damage, operating mode, and remaining useful life, the Predix Digital Twin can provide recommendations about inspection, maintenance and the optimal schedule for shop visits. For one Predix client, the savings in optimal inspection and planned maintenance schedule resulted in annual savings of millions of dollars. Dynamic optimization using multiple predictions and simulations is another key element of using digital twins. For example, multiple continuous prediction digital twin models of various engine parts and failure modes are being used together by one customer using Predix. The digital twin lets the client run potential scenarios of flight routes and schedules to see the effect that would have on costs and reliability, and the client was able to save millions of dollars annually with dynamic optimization. Harsh operating environmentsDigital twins are an ideal solution where customers have physical systems that have harsh operating environments, but need to carry out performance prediction and early warning prediction. A typical case of this is that of gas turbines. There are limited sensors in power generation gas turbines due to the very high temperatures and harsh operating environment. A Digital Twin performance model can be used to estimate the internal state of the turbine. These performance digital twin models are continuously tuned to account for the degradation of the power generation gas turbine, and are used for performance forecasting and optimizing the operation of the turbine. The output of the model is also used by early warning prediction and fault diagnostics models. Closed Loop ControlsDigital Twins can also be used for closed loop controls and real time optimization. One example of this is that of a combined cycle gas turbine (CCGT) power plant. Here, the digital twin model is being used to identify optimal control set points to reduce fuel consumption by more than 1%.

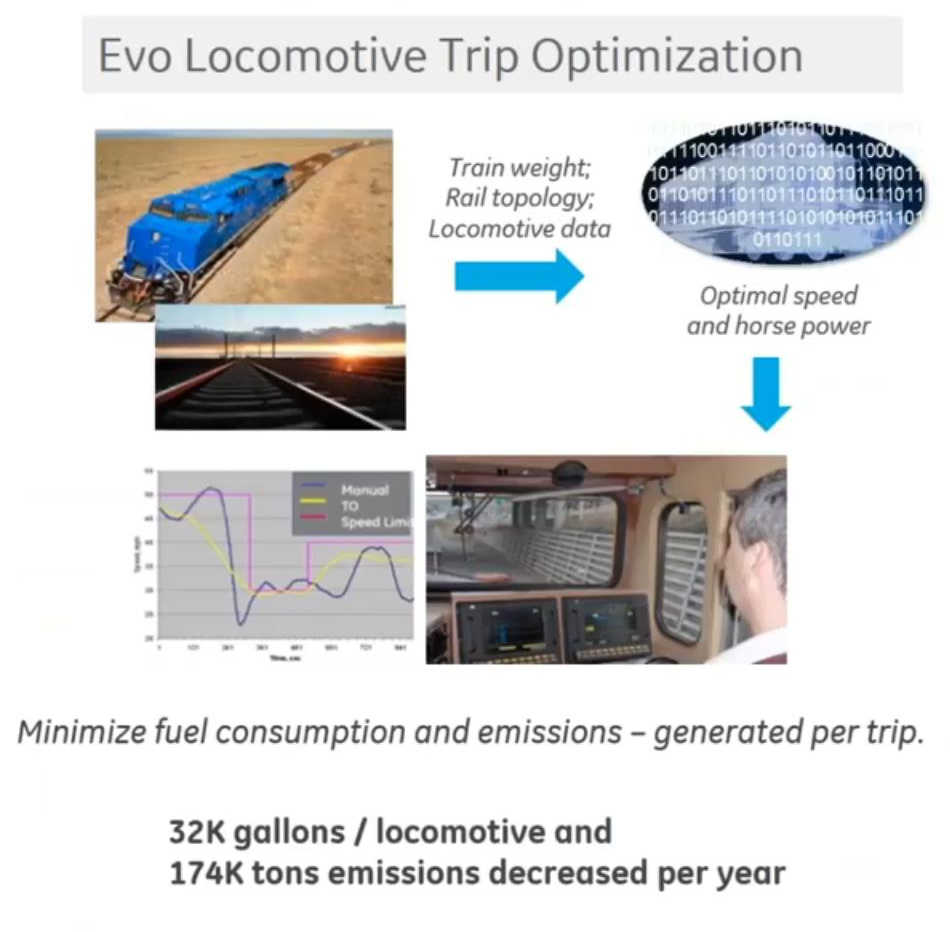

A similar example is a locomotive trip optimizer. North American railroads consume 4 billion gallons of fuel annually, which accounts for 25% of their operating costs. GE’s Trip Optimizer is digital twin-based control system that can be used by the crew or dispatcher to use the least possible fuel while still arriving on time. The optimal driving solutions are computed on-board, and executed in a closed loop using GPS-based navigation. The trip optimizer uses train, track and locomotive engine digital twin models, and the train and track parameters are adapted online to reduce model errors. This has resulted in an average fuel saving of ~32,000 gallons per locomotive per year. It has also cut emissions by 174,000 tons.

More than a modelWhile the model is an important element of the digital twin, its creation is more than a simple modelling exercise. A digital twin is a software object that bundles data with intelligence, and that is designed by assets experts with a business outcome in mind. The idea of the digital twin has existed for the majority of the 21st century, but systems such as Predix have now made it possible to connect industrial systems, digital representations, and machine intelligence to achieve real results. You may not have worked on or with a digital twin yet, but it's only a matter of time before you do.

More InformationRelated ArticlesPredix - A Platform for the Industrial Internet Of Things IoT Anomaly Detection Using A Kalman Filter How to Authenticate a Device in the Industrial Internet of Things

To be informed about new articles on I Programmer, sign up for our weekly newsletter, subscribe to the RSS feed and follow us on Twitter, Facebook or Linkedin.

Comments

or email your comment to: comments@i-programmer.info |

|||

| Last Updated ( Friday, 06 October 2017 ) |