| Arduino 3D Printing And CNC Machines |

| Written by Harry Fairhead | |||

| Saturday, 04 October 2014 | |||

|

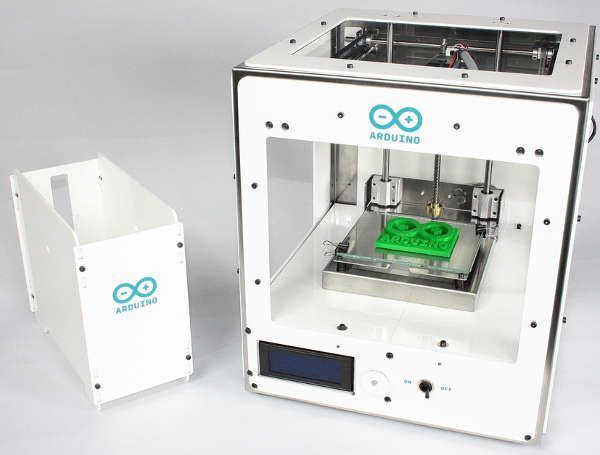

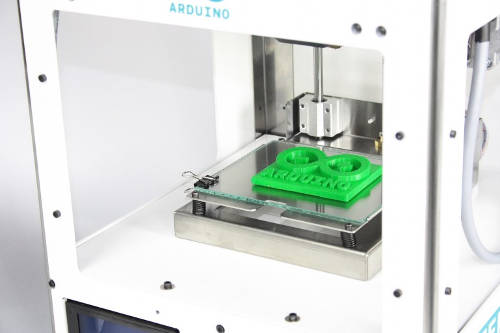

October 3rd was National Manufacturing Day in the USA. What has this to do with software? Everything. We tend to forget that just about everything we do with software is based on hardware and now our software has the ability to create solid, tangible things. Manufacturing is no longer a support for computing. With 3D printers, our software can produce real products. The 3D printer revolution still has a long way to go, but with Arduino on board it is getting closer to its target. The new Arduino Materia 101 is designed to be simple and with its cool blue Arduino logo you can't help but feel that it really is more approachable.

Overall the machine looks a lot like the Sharebot Kiwi-3D and uses the same material and printing area. We will have to wait to see if there are any substantial differences in performance or UI. The Materia 101 is expected to cost $800 as a kit and $1000 for the fully-built version.

Of course, the original 3D printer is the CNC machine tool. These vary in size from a full metal milling machine to a small router. Although not really printers, in the the sense that they work by taking material away from a block rather than depositing it to create the shape, they have the advantage that the range of materials they can work with is much greater - anything from wood to high strength metals. If you want a tough, computer-generated component then a CNC machine is what you need. As a demonstration of how CNC works the following video explains how a 3D model of a face was constructed - yes CNC machines can be accurate - from high density foam. Next the same 3D model was rendered using a three-color powder printer. A powder printer works by "inkjet" printing glue onto a layer of powder. Once the layer is complete, another layer of powder is deposited and the print head once again deposits glue.

More InformationRelated ArticlesNew Version of OpenCV in Alpha 3D Printing: Build Your Own 3D Printer and Print Your Own 3D Objects Dismantle That 3D Printer - Build An Air Hockey Robot Instead! Intel Inside - The Arduino Galileo Militarizing Your Backyard with Python and AI

To be informed about new articles on I Programmer, install the I Programmer Toolbar, subscribe to the RSS feed, follow us on, Twitter, Facebook, Google+ or Linkedin, or sign up for our weekly newsletter.

Comments

or email your comment to: comments@i-programmer.info |

|||

| Last Updated ( Sunday, 05 October 2014 ) |