| Robots Build The Raspberry Pi |

| Written by Harry Fairhead |

| Sunday, 18 June 2023 |

|

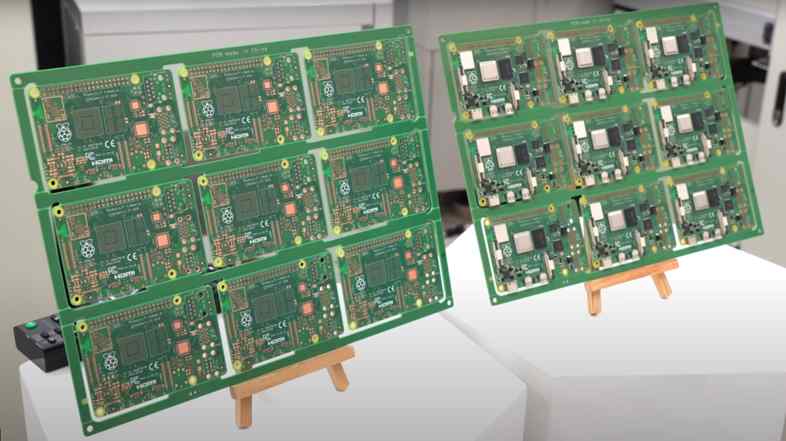

Raspberry Pi aficionado and prolific YouTuber, Jeff Geerling takes a guided tour of the factory in Pencoed where Raspberry Pis are built, or should that be "baked"? Among the work force on the assembly line is a team of robots. My recent report that the shortage of Raspberry Pis may soon be over includes a video in which Jeff Geerling interviews Eben Upton at Raspberry Pi headquarters, aka Pi Towers, in Cambridge. On his visit to the UK Geerling also visited the Pi factory and recorded another video for his YouTube channel: Operational since 1974, the Sony Tech Center is located in Pencoed, Bridgend, South Wales, which is where Raspberry Pi Founder and CEO Eben Upton was born and went to school. The facility was originally built to manufacture televisions, but it has since expanded to produce a wide range of electronic products, including, since 2011, the Raspberry Pi. Employing over 2,000 people, the Sony Tech Center is a major source of innovation, and it has helped to put Wales on the map as a center for electronics manufacturing. Recently we reported that Sony is making further "strategic investment" in Raspberry Pi and is planning to bring its AITRIOS platform to the Raspberry Pi user and developer community - and an AITRIOS box actually makes a fleeting appearance in the video. At the start of the video Geerling tells us that in the past decade the Pencoed factory has made nearly 50 million Raspberry Pis. While it is the Pi 3B+ that we actually see being built, according to lead engineer Andrew Puntan the factory can produce a Pi 4 "every 3.14 seconds" which amounts to 180,000 to 200,000 a week. The process of making a Raspberry Pi starts in the factory's SMT (Surface Mount Technology) department where the circuit boards, which arrive in a panel of 9, get populated. First solder paste is applied to the board by a screen printer, then the components are applied with the very small components first as the head that pushes the components into the paste with a puff of air has to get very close to the board. The small components go on the underside of the board, then larger components on the topside. Next the boards are slowly baked by passing through a long oven. At the next stage, larger through-hole components like Ethernet ports, USBs and headphone jacks are placed one-by-one by robots - programmed by humans of course. While the robots make the process faster, they aren't perfect and the final components have to be placed by hand. As well as robots building Pis, Greeling also points out that Raspberry Pis, specifically the Revolution Pi, an open source industrial packaged Pi, are involved in controlling the manufacturing process of other Raspberry Pis. He claims to have counted around 15 of them during his visit and is pleased to be able to report on Pis building Pis!

More InformationRaspberry Pi Foundation website Related ArticlesRaspberry Pi - You Can Have 10 Zeros! Updated Raspberry Pi Most Popular Industrial IoT Device! Pi Compute Module 4 - Time to Take Industrial Pi Seriously The New Raspberry Pi Pico Breaks The Mold Raspberry Pi 4 Sets New Performance High At Same Cost To be informed about new articles on I Programmer, sign up for our weekly newsletter, subscribe to the RSS feed and follow us on Twitter, Facebook or Linkedin.

Comments

or email your comment to: comments@i-programmer.info

|

| Last Updated ( Sunday, 18 June 2023 ) |