| Low Cost Robot Wins Amazon Robotics Challenge |

| Written by Alex Armstrong |

| Tuesday, 01 August 2017 |

|

A team from the Australian Center for Robotic Vision has won the 2107 Amazon Robotics Challenge with a low-cost robot with an innovative design that works like a 3D printer mechanism. The contest was first held at the 2015 IEEE International Conference on Robotics and Automation (ICRA). Last year, as this time, it has become part of the annual RoboCup. For this third event 16 teams from 10 countries travelled to Nagoya, Japan to compete for a prize pool worth $270,000. The contest is intended to: strengthen ties between the industrial and academic robotics communities and to promote shared and open solutions Some changes were made this year to make it more difficult and to encourage broader participation from multiple robotics fields and there were three stages to the contest which took place over four days.

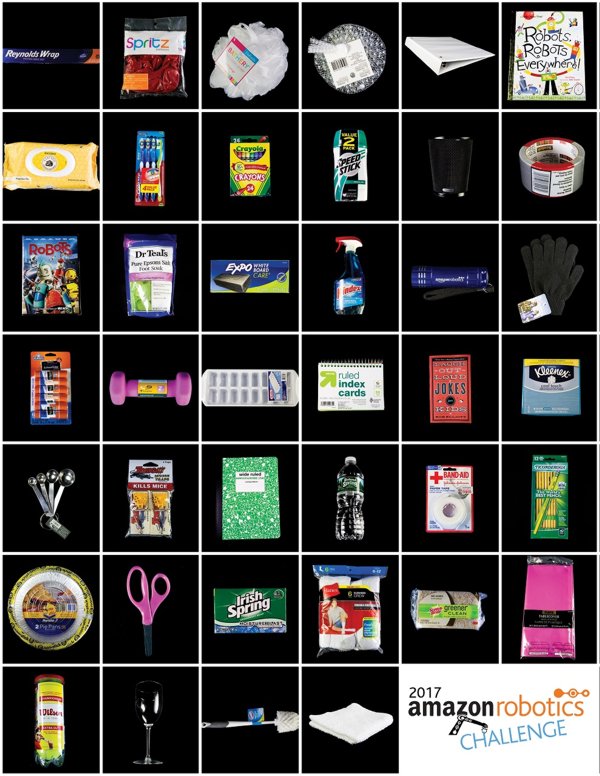

Solutions needed to combine object recognition, pose recognition, grasp planning, compliant manipulation, motion planning, task planning, task execution, and error detection and recovery to successfully pick and stow a set of items, some of which had been disclosed months in advance of the finals:

Teams were judged based on how many items were successfully picked and stowed by their robots in a fixed amount of time with penalty points deducted for damage to products and boxes.

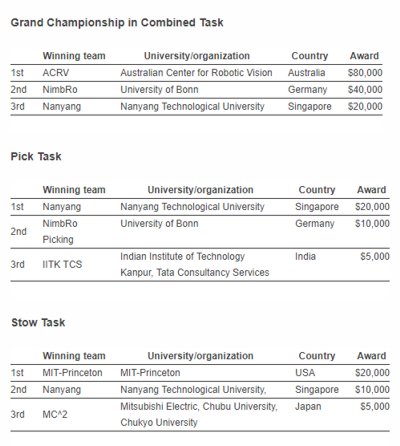

At the end of the first day the Australian team, comprising researchers, PhD candidates and undergraduate students from Queensland University of Technology, the University of Adelaide and the Australian National University was well down the field after it has suffered a catstrophe - a broken wrist - so its jubilation in winning the Grand Championship, with a cash award of $80.000 US, was all the greater. The complete list of prizes awarded is as follows: The winning machine, Cartman, was thought to be the lowest cost robot at the event. According to team member Prof Jonathan Roberts, robotics lab leader at Queensland University of Technology: "The parts for the robot were cheap by the standards of typical industrial robots and it could be built for under 30,000 Australian dollars ($23,935)." Rather than a conventional robot arm, it uses a frame to move in straight lines across three axes that are at right-angles to each other - a "Cartesian co-ordinate system" similar to that used by container port cranes. The mechanism, which provides six degrees of freedom, supports a rotating gripper that uses suction cups and a two-fingered claw to grasp and manipulate items.

Roberts explained: "It works a lot like a 3D-printer mechanism, where the robot manipulator is moved backwards and forwards and up and down. This made for a more accurate and simple system." Commenting on the outcome of this year's event, Joey Durham, Contest Chairperson and Manager of Research and Advanced Development for Amazon Robotics said: “The versatility of recognition capabilities in an unstructured environment and the dexterity of grasping mechanisms was truly impressive."

More InformationAmazon Robotics Challenge Winners Announced

Related ArticlesAmazon Robot Picking Challenge 2015 Amazon Robot Picking Contest Results Robots Improve Performance At Warehouse Picking To be informed about new articles on I Programmer, sign up for our weekly newsletter, subscribe to the RSS feed and follow us on Twitter, Facebook or Linkedin.

Comments

or email your comment to: comments@i-programmer.info |

| Last Updated ( Tuesday, 01 August 2017 ) |